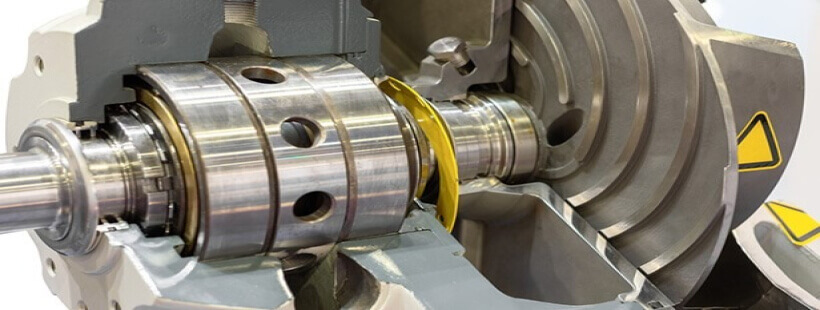

The mechanical seal is a part of the pumping system whose performance is critical and its maintenance is usually forgotten. Excessive leakage from the seal due to improper maintenance or working conditions beyond the permissible limits can cause various hazards such as ignition, health or environmental problems; therefore, it is necessary to use a regular and practical sealing maintenance program to ensure correct operation and increase the lifespan. The following are the things that should be considered in maintaining this system.

Estimation of working conditions:

Temperature, pressure and speed are among the factors that affect the wear of sealing elements and the increase of leakage; therefore, it is necessary to know the operating conditions to choose a suitable sealing system. The combination of process variables for mechanical sealing creates special conditions that require system adjustments to accommodate problems such as evaporation, freezing, or overheating.

It is very difficult to keep the efficiency of the sealing system high for applications where there is high temperature, pressure and speed or where the viscosity of the fluid is high. In such a situation, it is recommended to use strong and resistant seals to increase the service and repair time of the system.

Durability of sealing surfaces against fluid:

In most systems, the fluid being pumped is also used as the lubrication fluid. Fluid properties, like sealing properties, are a function of temperature and working pressure that must be considered. These properties include the thickness of the layer between the elements, purity, toxicity and flammability. Hard-hard seals are more suitable for dirty fluids containing solid particles, but without a fluid layer between them, they will wear out sooner. In contrast, hard-soft seals will last longer in the absence of lubricating fluid.

Attention to the reasons for the wear of sealing surfaces:

Excessive leakage is usually a sign of wear on the contacting surfaces, but this problem can be caused by more serious problems such as bearing failure and shaft bending. If the wear is due to the contact of rough surfaces, we can see its signs, which are the presence of grooves and chips on the surface.

Reduce vibrations:

Try to use the pump close to the best performance point. When you move a lot away from this point, cavitation will be created in the pump and as a result, the amount of pump vibrations will increase. The sealing system and especially parts such as o-rings, polymers, springs, driving pins and adjustment screws are sensitive to vibration, and the presence of high vibrations will reduce their lifespan.

Proper lubrication:

Mechanical seals depend on an oil film between contacting surfaces to control heat and friction. In most cases, the pumped fluid provides the required oil layer while contacting the sealing surfaces; therefore, to protect the seal, the pump should be prevented from running without fluid.

To be sure, controllers equipped with a flow sensor or a pump performance monitor can be used to avoid problems. In general, the performance of the sealing system in applications where the pump works continuously is better than in applications where the pump is cycled on and off. On average, the time of using mechanical sealing is considered to be at least two years. As mentioned earlier, this duration depends on variables, working conditions and design constraints. Familiarity with the system and its limitations can help to prevent, recognize and solve sealing problems.