VS6 pumps Introduction

VS6 pumps are single or multi-stage vertical pumps specially designed to move fluids with high pressure and medium flow. These pumps are designed according to the API 610 standard and are used in the oil and gas, petrochemical, and other industrial applications that require pumping fluids in harsh conditions.

Structure and design of VS6 pumps

Multi-stage design: VS6 pumps consist of one or more impellers mounted in series on a long shaft. Each impeller causes an increase in fluid pressure, and as a result, these pumps can produce very high pressures.

Vertical design: These pumps are installed vertically, which saves space. This feature is very suitable for environments with limited space.

Segmental Casing: The housing of VS6 pumps is designed in a sectional way. This design allows each pump section to pressurize the fluid separately, which helps achieve high pressures.

Bearings and bushings: VS6 pumps have axial and radial bearings that make the pump stable. These bearings are located on the top of the pump and because they are separated from the fluid, they have less possibility to damage due to corrosion. Intermediate bushings are also used to maintain the shaft.

Sheath or diffuser (Diffuser): In some VS6 designs, diffusers are used to reduce fluid velocity and convert kinetic energy to pressure. This increases the efficiency of the pump.

Applications of VS6 pumps

VS6 pumps are used in a wide variety of industrial applications due to their ability to generate high pressure. Some common uses include:

Oil and gas industries: For pumping liquid hydrocarbons, liquefied gases, and other fluids in refinery and petrochemical processes.

Chemical industry: For transporting corrosive or hazardous chemicals that require high pressure to move.

Power plants: For pumping boiler feed water and cooling systems, where high pressure and controlled flow are required.

Water and sewage: In water transmission systems with long distances that require high pressure to move water.

Features and benefits of VS6 pumps

Ability to create high pressure: The multi-stage design of these pumps allows them to generate very high pressures, which are essential for certain industrial applications.

Saving space: The vertical design of these pumps makes them easy to install in environments with limited space.

High reliability: The use of corrosion-resistant materials and robust design increases the useful life and reduces the need for frequent repairs.

High efficiency: Optimal design of propellers and diffusers increases pump efficiency and reduces energy consumption.

Disadvantages of VS6 pumps

High cost: Due to the complex design and the use of high quality materials, the cost of manufacturing and maintaining these pumps is higher than simpler pumps.

The need for careful installation and maintenance: The installation of these pumps requires high precision to ensure their optimal performance. Also, their maintenance requires special expertise and equipment.

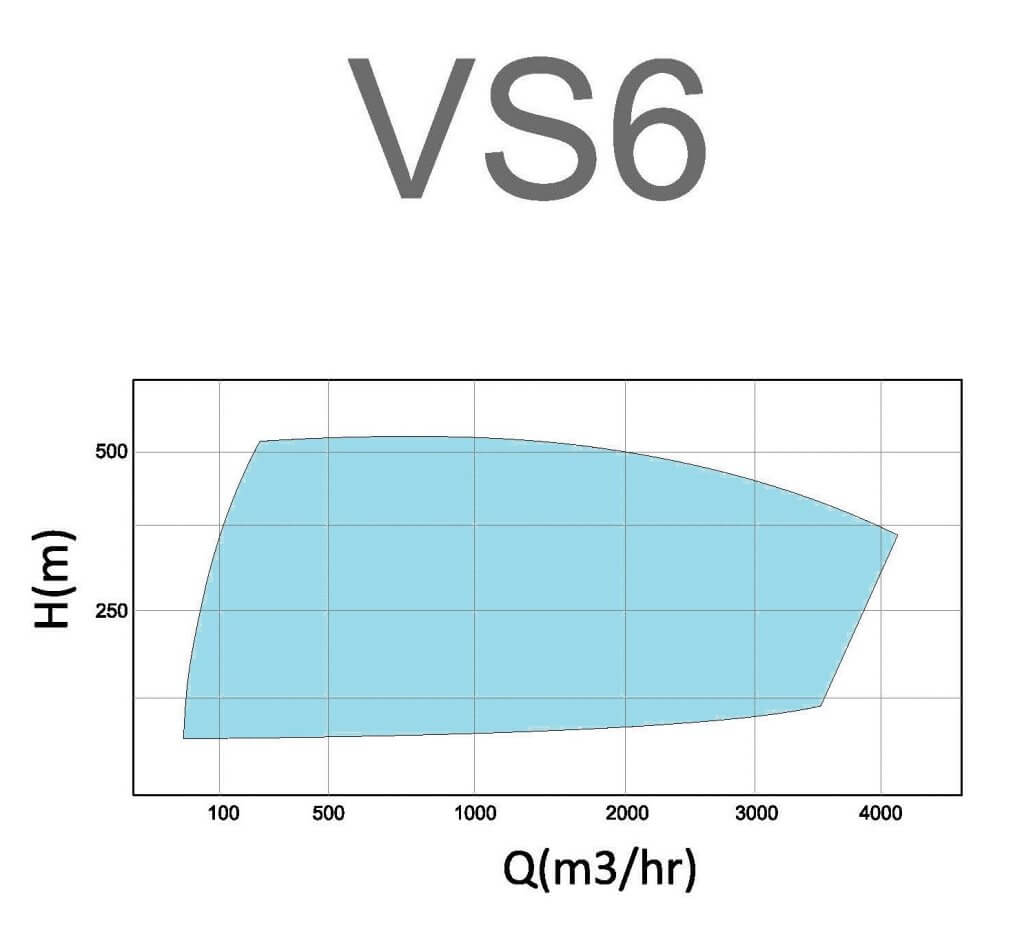

Restrictions in flow: VS6 pumps are typically designed for medium flow rates and may not be suitable for applications requiring very high flow rates.

VS6 pumps are widely used in various industries that need to pump fluids under high pressure due to their ability to create high pressure and vertical one or more stages design. By providing reliable performance and high efficiency, these pumps are one of the vital components in industrial processes. However, high construction and maintenance costs and the need for precise installation are some of the challenges associated with these types of pumps.