Introduction to Submersible Pump

The Submersible Pump is a multi-stage pump that has an electric motor and is used for pumping water or other liquids from deep wells with a vertical centrifugal system.

A Submersible Pump is a type of centrifugal pump that works the same way as floor centrifugal pumps.

The way it works is that the fluid enters the pump from the center of the impeller and after leaving the impeller outlet, it enters the next floor and exits from the outlet of the final impeller, which increases the water pressure.

This type of pump pushes the water towards the surface by increasing the rotational movement (speed) or kinetic energy, and the diffuser blades convert this kinetic energy into pressure.

Typically, it does not require priming or initial setup as it is completely submerged in the fluid. The operation of the Submersible Pump is slightly different from the jet pump.

Jet pumps move fluid by suction while submersible pumps move fluid by pushing. Since this is a type of centrifugal pump, its operation is very similar to other types of centrifugal pumps.

Application of Submersible Pumps

The application of the Submersible Pumps is generally in water or sewage, but in general these pumps are used in various industries and jobs such as agriculture, drainage, firefighting, water purification centers and salt water transfer, gardening, household use, as well as oil and gas industries.

Submersible pumps are usually very reliable and can perform well in harsh conditions. They are made with durable iron castings and are epoxy coated to protect against corrosion.

Sewage:

They are widely used in the sand and sewage industry in pump and lift stations because they are compact and less expensive to install than other pumps.

Wastewater treatment: This operation requires a Submersible Pump that can move solids out of the pump inlet without clogging.

These pumps often reduce sewage material to finer particles for easier handling and downstream treatment.

Tank pumping:

A Submersible Pump is often used to remove water that is in a low-lying area or pit where water may have collected.

For example, removing waste material ponds from mining operations or removing water from the basement of a building due to flooding.

Dredging:

These pumps are used in ports for dredging a port. They must be specially designed to handle liquids with high solids content.

Wells:

In water wells and boreholes, these pumps are used to raise water to the surface. The oil and gas industry widely uses submersible pumps to lift oil from deep wells to the surface.

Mining:

This pump is also used in mines, which are designed differently from the pumps used in the oil and gas industry.

They have to deal with harsh conditions because mine water is highly acidic and carries suspended solids.

Oil and gas:

Many of these pumps in the oil and gas industry work on the principle of electric floating pumping.

It is a cost-effective way to remove large volumes of fluids from deep wells. The engines used in this system are designed to work at high temperature and pressure. They require special power cables and can be expensive to operate.

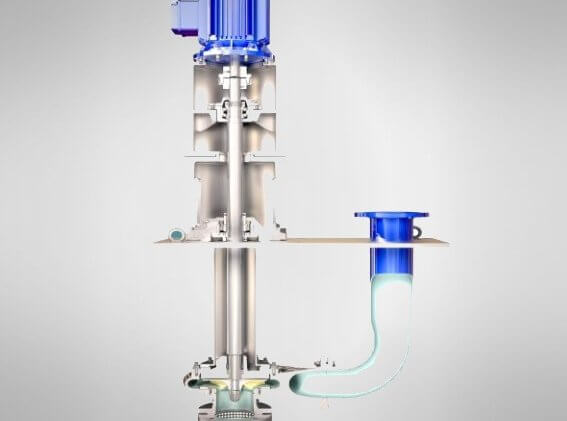

Submersible Pump components

Stator:

The stator is an important part of the energy conversion of the floating pump motor, which is called the stator because of its immobility.

The stator consists of a shell, stator core and stator windings. Three-phase alternating current is transferred to the stator winding through a cable line and a rotating magnetic field is created in the stator core.

Shell by casting processing, rolling steel after welding processing or direct processing by pipe Seamless steel, cover assembly reinforcement, robot requirements and the inner circle of the core body maintain a highly concentric, little stator-rotor friction may occur.

The stator core is the guide magnet of the motor, after being compressed by the core, it is folded by the silicon steel sheet and fixed axially through the retaining ring, and the inner circle of the iron core is provided with a slot for placement.

Rotor:

The rotor is also an important part of the energy conversion of the Submersible Pump motor.

The rotor current interacts with the rotating magnetic field of the stator and produces an electromagnetic torque that causes the motor to rotate.

The rotor consists of a rotor core, a balance washer and a rotating shaft.

The rotor core is the guide magnet of the motor. It is folded by the silicon steel sheet and pressed on the rotating shaft.

The core is fixed in axial direction and circumferential direction to prevent relative movement. Cast aluminum rotors often omit the key, and the iron core of the rotor is attached directly to the shaft by the wasted heat of the cast aluminum.

Small capacity motors are mostly made from cast aluminum rotors and larger capacity motors are mainly made from copper strips.

The rotor parts rotate at a high speed, so the dynamic balance of the rotor must be corrected by the weight removal method to ensure good mechanical performance of the floating motor.

reduce vibration and noise, and generally have a balance washer on the rotor. The most common material for the rotating shaft of the floating motor is steel 45.

Air gap:

The stator and rotor have a smaller but uniform air gap in the radial direction. The air gap has a huge impact on engine performance.

A smaller air gap can be used to direct the flow and improve the power factor. But according to the level of the manufacturing process.

the air gap of the small Submersible Pump is 0.5 to 0.8mm, and the air gap of the medium power submersible sewage pump is 0.8 to 41mm. The air gap of the large flow Submersible Pump is usually no more than 2mm.

Bearing:

The small power Submersible Pump uses two rolling bearings with one thrust bearing, which is a medium power combination of rolling and thrust bearing.

The large-power Submersible Pump, even with the use of cylindrical rollers and a pair of tapered rollers, must withstand radial force and axial force.

The lower bearing and the rotating shaft must be clamped to prevent axial movement of the main shaft during operation. QS floating pump is often used to guide the bearing.

Sealing System:

In order to equip the Submersible Pump in order to prevent water from entering the engine, static and dynamic sealing is done.

Dynamic sealing is mainly created around the shaft. The static sealing of the main parts is often done by O-Ring, and the output part of the cable also has a fixed seal, which is often of the type A screw is used.

For dynamic sealing, integrated seals, single head mechanical seals, double mechanical seals, labyrinth seals or skeleton seals are generally used. In most cases, graphite, ceramic, carbide mechanical seals are used.

Wiring groves and cables:

The cable of the float pump and the motor winding must be stably connected in the wiring compartment.

When ensuring no vibration of the motor, displacement and daily operation, the lead of the cable and the motor coil will not be lost. Cable joints should be made of polyethylene or PVC insulation and nylon sheath as mechanical protection.

Cables and Motor windings are often connected by terminals. The cable voltage is not less than the rated voltage of the motor.

the current is not less than the rated current of the motor, and it must be in accordance with the Submersible Pump using the environment, temperature, pressure, corrosion and other reasonable choices.

Impeller:

After the rotation of the impeller, the liquid is guided by the blade, the pressure and speed increase and the energy of the engine is transferred to the liquid.

The impeller is generally made of different materials such as HT200 cast iron or stainless steel.

For wear-resistant use, you can use cast steel zGlcrl3, ductile iron or high chromium cast iron QT600-3. You can use copper alloy or stainless steel for the required corrosion resistance.

Advantages of Submersible Pump

No need to fill: This advantage helps make this pump one of the most accessible classes to work with and ensures that you don’t spend a lot of time or money on them or upgrading them.

High efficiency: The low level of energy required to operate these types of pumps makes them very efficient and a great choice for those who don’t have a lot of money.

Convenient and portable: Submersible Pumps are very convenient to move because they are usually small, light and portable.

Most of them have a handle, so they are easy to carry wherever they are needed.

Cavitation: Since floats are completely submerged, they are not prone to cavitation.

Self-priming: Since a Submersible Pump is submerged in the liquid it pumps, it is already “primed” and does not require priming.

This saves money, but it will require maintenance if the pump that needs to be putty works while it is drying.

Choices: You can find a wide variety of flotation options for your pumps, making them a great choice for those who have many uses for these units.

Quiet Operation: Most floating units of this type are very quiet because they are underwater and because cavitation or pump pressure surges never cause problems with this unit.

Highly Corrosion Resistant: Since these pumps must be hermetically sealed, they must be made of materials that are highly corrosion resistant, such as stainless steel.

Also, another advantage of the sealing process is that the inside is not exposed to oxidation or corrosive substances.

Versatile: As we mentioned before, Submersible Pumps have many more uses than under ground pumps.

Some of them even operate semi-submerged, and some are designed to handle sewage and other solids.

Electric: Submersible Pumps are electric. All you need to run it is access to a power outlet. Most of them have long power cables of 16 meters, which ensures that you always have access to electricity.

Save space: Any other type of pump needs to be placed outside of the fluid you’re pumping and takes up space, but this pump doesn’t take up extra space except for the power cord.

Safety: The deep well Submersible Pump is sealed and underwater, which makes it much less dangerous for children than other pumps.

A pump with external moving parts is dangerous for children and even adults. You can also place a board over your pump to hide it even more.

Less Maintenance, Longer Life: The factors we’ve listed here combine to produce a pump that requires almost no maintenance and lasts longer than other types of pumps.

Choosing the right Submersible Pump

When choosing between the types of Submersible Pumps available, four main features are important to consider:

1- Maximum discharge flow: This parameter shows the maximum flow produced by the pump. This value depends on the pressure head that the pump must apply.

2-Maximum Discharge Pressure (Maximum Discharge Head): This is the maximum pressure that the pump can produce.

3- Power: This value expresses the amount of energy consumption. One horsepower is equal to 745.7 watts and is defined as work done at a rate of 550 foot-pounds per second.

4- Outlet diameter: This is the size of the drain connection or pump outlet. In order to choose a floating electric pump, it is enough to have flow rate and head.

But in many cases, according to the existing pipelines, the diameter of the pump outlet can be one of the selection criteria. But the flow rate is a function of the outlet diameter.