BB5 pumps Introduction

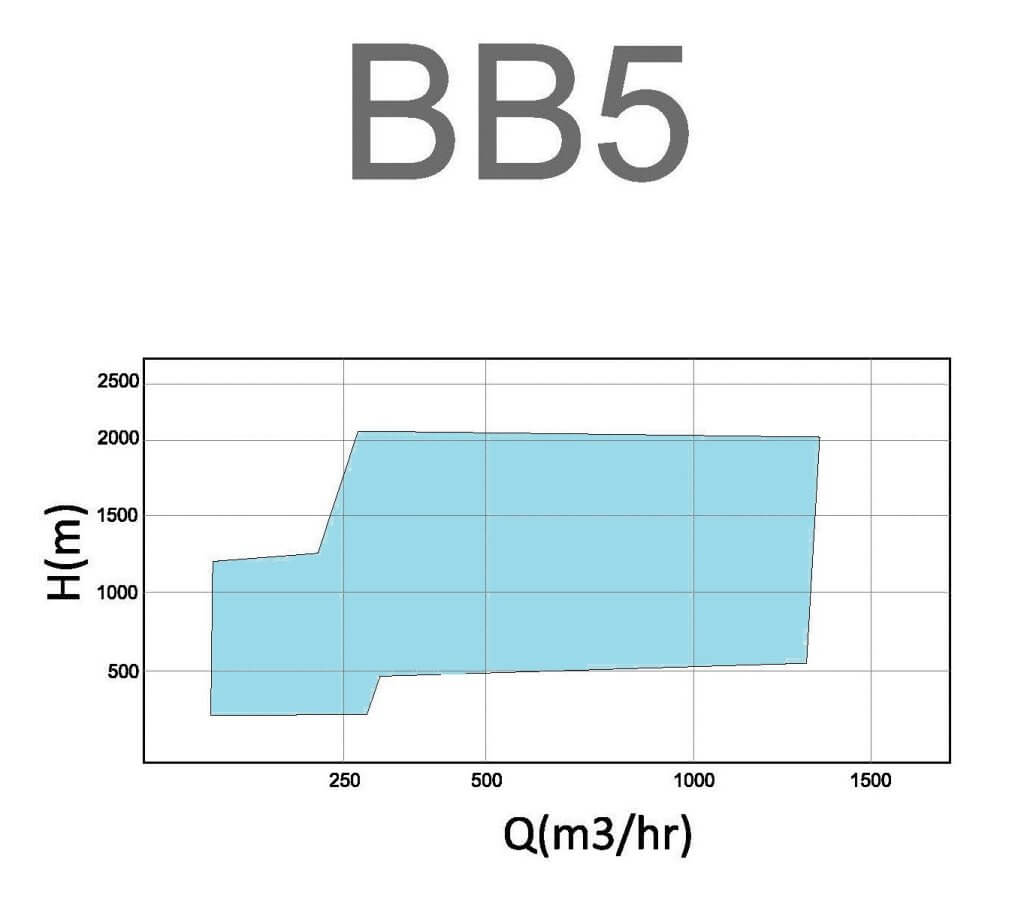

BB5 pumps are one of the types of multi-stage horizontal centrifugal pumps, which are specifically designed for heavy industrial applications and moving liquids with very high pressure and head. Due to their special design and unique features, these pumps are widely used in industries that need to transfer liquids under difficult conditions and at high pressure.

Design and structure of BB5 pumps

Multi-Stage Pumps: BB5 pumps are designed as multi-stage, which allows for increased output liquid head and pressure.

Horizontal axis: These pumps are designed horizontally and the pump axis is placed horizontally.

Radial body disassembly: The BB5 pump body can be radially disassembled, which facilitates easy access to internal pump components for maintenance.

Multi-stage: The use of multi-stage impellers in BB5 pumps increases the output pressure and pump efficiency.

Resistant structure: The design and resistant structure of these pumps allows withstanding harsh operating conditions.

Double-wall shell: This pump includes two outer and inner shells.

Attributes of BB5 pump

High stability: due to the design and use of double-sided supports, BB5 pumps have high stability.

High efficiency: These pumps are designed to transfer liquids with high pressure and head and maintain their efficiency in heavy industrial conditions.

Easy maintenance: radial body disassembly design and easy access to internal components make maintenance and repair of these pumps easy.

Optimal energy consumption: due to optimal design and the use of modern technologies, energy consumption in BB5 pumps has been reduced compared to other pumps.

Reduction of vibration and noise: The special design of the impellers and the solid structure of the pump reduce vibration and noise during operation.

High efficiency: due to the use of multiple impellers and optimal design, these pumps have high efficiency.

Applications of BB5 pumps

Oil and gas industries: used to move crude oil, refinery products and chemicals at high pressures.

Power plants: It is used for feeding boiler systems, cooling systems and other applications requiring high pressure.

Chemical industry: for handling various chemicals at high pressure.

Water and sewage: It is used in water supply and sewage treatment systems.

Petrochemical: for transporting petrochemicals and petroleum products.

Advantages of BB5 pumps

- Long life: due to the use of durable design.

- Flexibility in application: ability to be used in various industrial conditions and applications.

- Reducing maintenance costs: due to the ease of access to components and reducing the need for frequent replacement of parts.

- Pressure increase: multi-stage design and the use of multiple impellers increase the pressure and pump head.

- Reduction of vibration and noise: The special design of the impellers and the solid structure of the pump reduce vibration and noise during operation.

- High pressure tolerance: Due to the outer shell in these pumps, it is possible to tolerate high pressures and this issue makes the use of these pumps special.

Disadvantages of BB5 pumps

Initial cost: BB5 pumps have a higher initial cost than some other pumps.

Required space: Due to the horizontal design and large body, they require more space than some vertical pumps.

Complexity of repairs: Due to the multi-stage and more complex design, the repairs of these pumps may be time-consuming and require more expertise.

BB5 pumps are known as one of the most widely used and efficient options in various industries. Due to the mentioned features and advantages, these pumps are the right choice for applications that need to move liquids with very high pressure and head. These pumps are especially in demand in the oil and gas, petrochemical and power plant industries due to their high efficiency and longevity.