VS3 pumps Introduction

VS3 pumps are part of vertical pumps and are specially known as vertical centrifugal pumps with a special design for installation in tanks or wells. These types of pumps are designed and manufactured based on the API 610 type VS3 standard, which are specially suitable for industrial and process applications with high flow and low pressure.

Structure and design:

Verticality: VS3 pumps are installed vertically, so that the impeller and hydraulic components are in the fluid or the lowest part of the tank. This design allows the fluid to enter the pump easily.

Sheathed Design: Many VS3 pumps are equipped with an outer sheath or housing that protects the shaft and other internal components. This design helps reduce vibrations.

Bearings: VS3 pumps usually have axial and radial bearings, which contribute to the stability of the pump and its long life. Middle bushings are also used to keep the shaft.

Applications:

VS3 pumps are mainly used in industries that need to pump fluids vertically from tank to the top of tank . Some of the common applications of these pumps are:

Petrochemical and chemical industries: for transferring different fluids.

Oil and gas industry: for pumping fluids from reservoirs or oil wells.

Power plants: to supply cooling water.

Water and Sewerage Industries: To transport groundwater or wastewater.

Features:

High reliability: VS3 pumps have a long life and high reliability due to their robust design and the use of high quality materials for harsh and corrosive environments.

Minimal space requirement: Due to the vertical design, these pumps take up less horizontal space, which is very useful in places with limited space.

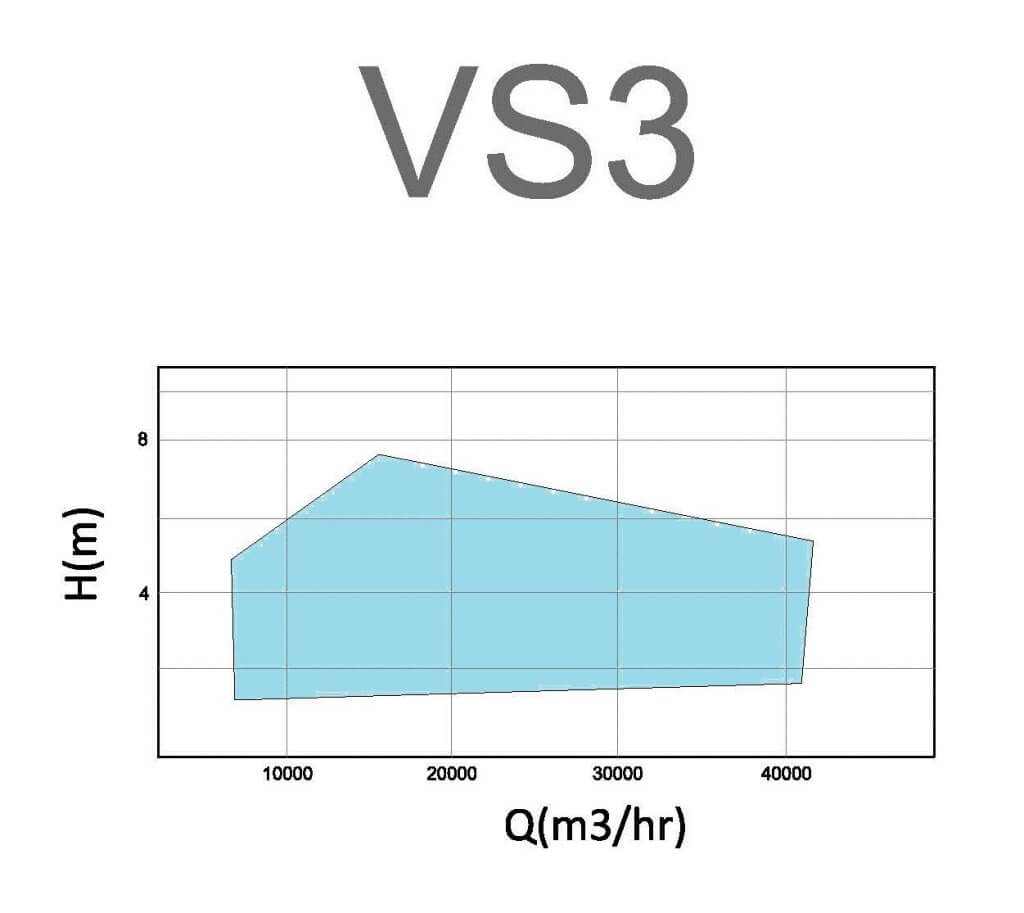

High efficiency: These pumps are optimized for moving fluids with high flow rate and low pressure.

Advantages of use:

The ability to work in harsh conditions: due to the strong structure and the use of corrosion-resistant materials.

Easy serviceability and maintenance: The modular design of these pumps helps in quick and easy service and repairs.

High flexibility: the possibility of customization based on specific customer needs.

Disadvantages of use:

High cost: These pumps are usually more expensive than similar horizontal pumps due to their complex design and use of high quality materials.

Need for accurate installation: Correct installation and setup is essential for optimal performance and avoiding potential problems.

Finally, VS3 pumps are highly demanded due to their special features in industries that need to pump high-flow rate and are considered as one of the critical components in these applications.