OH2 pumps

OH2 pumps are a series of single-stage horizontal pumps used for industrial applications. These pumps are designed and manufactured according to the API 610 standard, which is an international standard for centrifugal pumps. OH2 pumps are used in various industries such as oil and gas, petrochemical, refineries and chemical industries.

Features and specifications of OH2 pumps

Structure and design

Single-stage horizontal: OH2 pumps are horizontal and single-stage, that is, they have an impeller to move the fluid.

Detachable motor: The pump motor is seprate and connected to the pump using a coupling, which facilitates maintenance.

Installation type: The pumps have an integrated base and are installed from the middle support of the pump on the chassis bases. This installation method reduces vibration and increases the stability of the pump during operation. (Centerline – Mounted)

-

Construction materials

Different materials: Depending on the type of fluid and working conditions, OH2 pumps can be made of different materials such as stainless steel, special alloys and corrosion resistant materials.

Performance and capabilities

High efficiency: optimal hydraulic design that increases efficiency and reduces energy consumption.

Pressure and flow rate: the ability of the pump to transfer fluids with different pressure and flow rates depending on industrial needs.

Operating temperature: Ability to work in high temperatures and harsh environments.

-

Maintenance

Easy access: the possibility of easy disassembly of parts for repairs and maintenance.

Spare parts: the ability to access spare parts that reduces pump downtime.

Applications

- Oil and gas: movement of crude oil, oil products and chemicals.

- Petrochemical: transfer of different chemicals in production processes.

- Refineries: transportation of oil products in different processing units.

- Chemical industry: use in various processes of chemical production.

Advantages

- Advantage Durability and stability: due to the use of high quality materials and standard design.

- Reducing operating costs: due to high efficiency and reducing the need for frequent repairs.

- Flexibility: the ability to adapt to different operating conditions and diverse industrial needs.

OH2 pumps are one of the main choices of various industries for moving and transferring fluids due to their optimal design and performance.

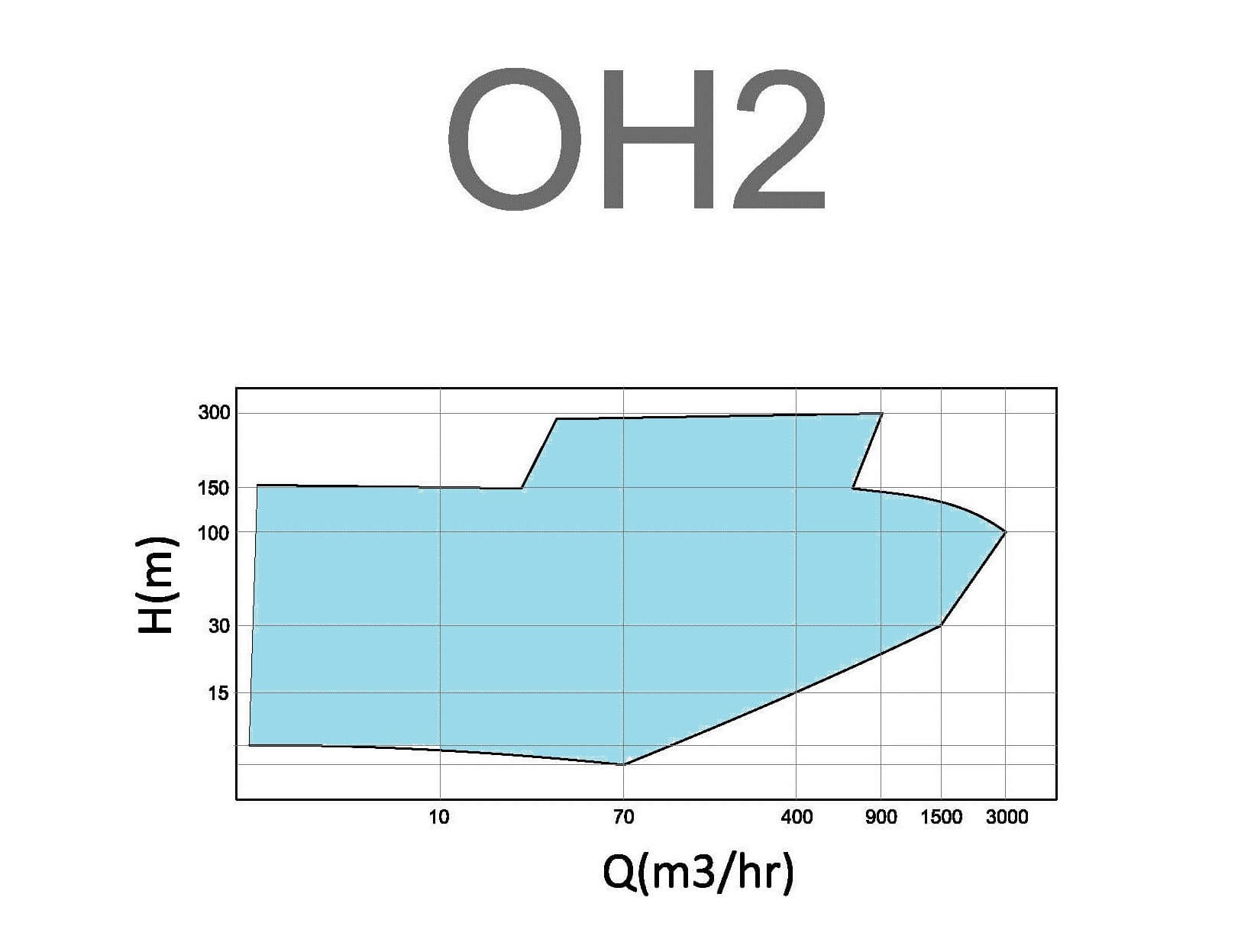

Performance range

Capacity (Q): up to 750 m3/h

Head: (H): up to 150 m

Speed (N): 980/1500/1180/3000 rpm

Working temperature (T): -50 to 350 °C

Working pressure (P): up to 25 Bar

| No. | Pump name | Maximum flow in 3000 RPM |

Maximum head in 3000 RPM |

Maximum flow in 1500 RPM |

Maximum head in 1500 RPM |

| 1 | OH2 25-200 | 13 | 67 | 7 | 16 |

| 2 | OH2 25-250 | 17 | 110 | 9 | 27 |

| 3 | OH2 25-315 | 21 | 160 | 10 | 40 |

| 4 | OH2 40-160 | 32 | 41 | 17 | 11 |

| 5 | OH2 40-200 | 40 | 67 | 20 | 16 |

| 6 | OH2 40-250 | 42 | 110 | 22 | 26 |

| 7 | OH2 40-315 | 48 | 155 | 25 | 39 |

| 8 | OH2 40-400 | —- | —- | 29 | 61 |

| 9 | OH2 50-160 | 63 | 41 | 31 | 11 |

| 10 | OH2 50-200 | 70 | 67 | 34 | 16 |

| 11 | OH2 50-250 | 80 | 105 | 40 | 27 |

| 2 | OH2 50-315 | 90 | 150 | 44 | 36 |

| 13 | OH2 50-400 | —- | —- | 51 | 61 |

| 14 | OH2 50-450 | —- | —- | 56 | 76 |

| 15 | OH2 80-250 | 125 | 108 | 65 | 27 |

| 16 | OH2 80-315 | 150 | 150 | 75 | 35 |

| 17 | OH2 80-400 | —- | —- | 90 | 60 |

| 18 | OH2 80-450 | —- | —- | 100 | 75 |

| 19 | OH2 100-250 | 250 | 108 | 120 | 25 |

| 20 | OH2 100-315 | 285 | 155 | 150 | 40 |

| 21 | OH2 100-400 | —- | —- | 160 | 60 |

| 22 | OH2 100-450 | —- | —- | 174 | 75 |

| 23 | OH2 100-500 | —- | —- | 200 | 100 |

| 24 | OH2 150-200 | 340 | 61 | 185 | 16 |

| 25 | OH2 150-250 | 410 | 106 | 210 | 25 |

| 26 | OH2 150-315 | 502 | 155 | 250 | 40 |

| 27 | OH2 150-400 | —- | —- | 300 | 60 |

| 28 | OH2 150-450 | —- | —- | 326 | 75 |

| 29 | OH2 150-500 | —- | —- | 345 | 100 |

| 30 | OH2 150-560 | —- | —- | 385 | 120 |

| 31 | OH2 150-630 | —- | —- | 400 | 150 |

| 32 | OH2 200-250 | 710 | 105 | 340 | 25 |

| 33 | OH2 200-315 | 805 | 155 | 405 | 40 |

| 34 | OH2 200-400 | —- | —- | 500 | 60 |

| 35 | OH2 200-560 | —- | —- | 600 | 120 |

| 36 | OH2 200-630 | —- | —- | 700 | 150 |

| 37 | OH2 250-315 | —- | —- | 635 | 40 |

| 38 | OH2 250-500 | —- | —- | 930 | 100 |

| 39 | OH2 250-560 | —- | —- | 1000 | 120 |

| 40 | OH2 250-630 | —- | —- | 1100 | 150 |

| 41 | OH2 300-630 | —- | —- | 1700 | 150 |