BB2 pumps Introduction

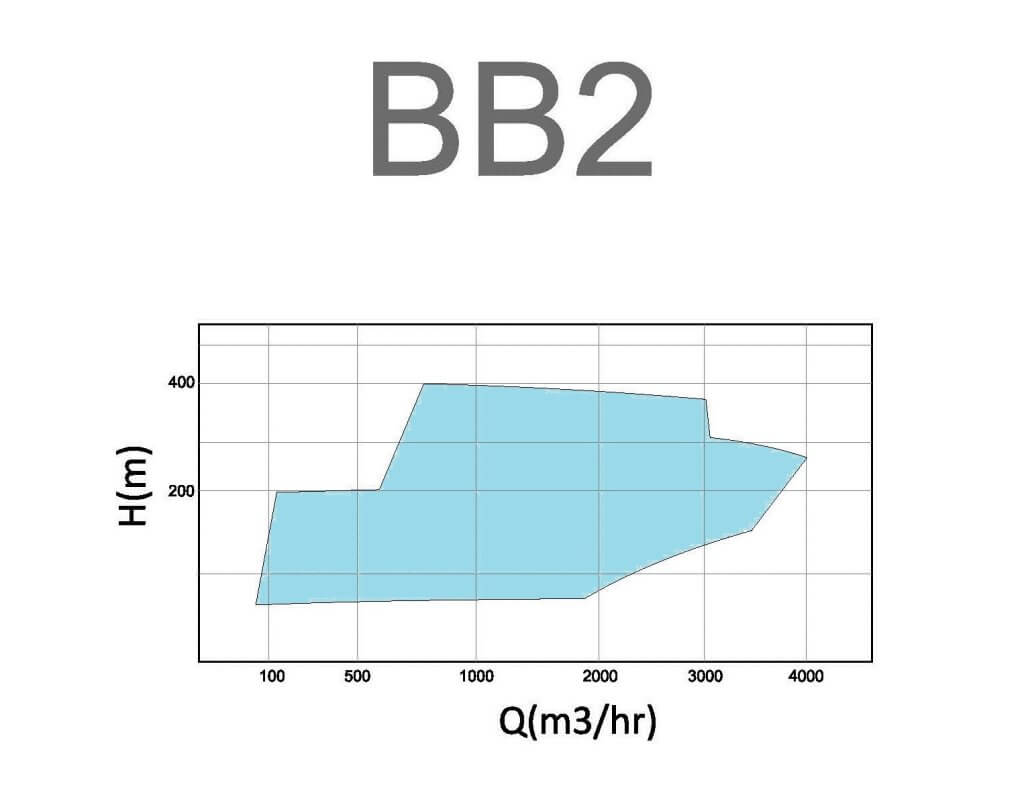

BB2 pumps are one of the types of horizontal centrifugal pumps that are used in various industries. Due to their special design and features, these pumps are used in moving various liquids, including liquids with low and medium viscosity, such as crude oil, petroleum products, and chemicals.

Design and structure of BB2 pumps

Single-Stage and Two-Stage Pumps: BB2 pumps can be designed as either single-stage or two-stage, allowing them to achieve different head or output pressures.

Horizontal axis: These pumps are designed horizontally and the assembly of the pump body is of radial type.

Body disassembly: The body of the BB2 pump is radially disassembled, which makes it easy to access the internal components of the pump for maintenance.

Two-suction impeller: In many BB2 pump models, a two-suction impeller is used, which increases efficiency and reduces vibration.

Attributes of BB2 pump

High stability: due to the type of design and the use of double-sided supports, BB2 pumps have high stability and resistance.

High efficiency: These pumps are designed to transfer large volumes of liquids with high efficiency.

Easy maintenance: radial body disassembly design and easy access to internal components make maintenance and repair of these pumps easy.

Optimal energy consumption: Due to the optimal design and the use of modern technologies, the energy consumption of BB2 pumps is reduced compared to other pumps.

Applications of BB2 pumps

Oil and gas industry: Used to move crude oil, refinery products and chemicals.

Power plants: used for cooling and water transfer systems.

Chemical industry: for handling various chemicals.

Water and sewage: It is used in water supply and sewage treatment systems.

Petrochemical: for transporting petrochemicals and petroleum products.

Advantages of BB2 pumps

- Long life: due to the durable design.

- Flexibility in application: ability to be used in various industrial conditions and applications.

- Reducing maintenance costs: due to the ease of access to components and reducing the need for frequent replacement of parts.

- Reduction of vibration and noise: The design of the double-suction impeller reduces the vibration and noise of the pump.

Disadvantages of BB2 pumps

- Initial cost: BB2 pumps have a higher initial cost than some pumps.

- Required space: Due to the horizontal design and large body, they require more space than some vertical pumps.

BB2 pumps are known as one of the most widely used and efficient options in various industries. According to the mentioned features and advantages, these pumps are the right choice for applications that need to move a large volume of liquids with stability and high efficiency. These pumps are especially in demand in the oil and gas, petrochemical and power plant industries due to their high efficiency and longevity.