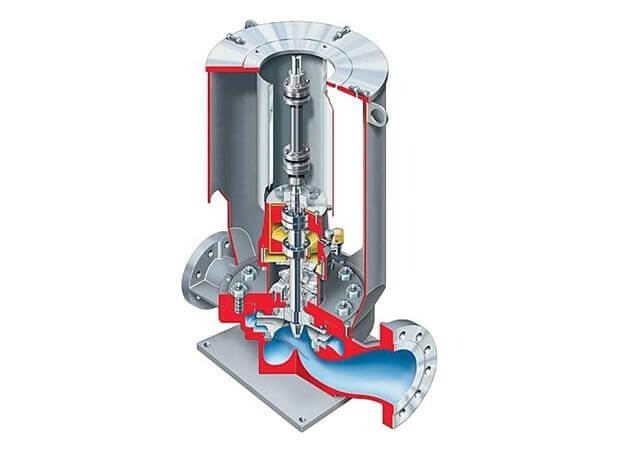

OH3 pumps

OH3 pumps are a type of vertical centrifugal pumps that are designed and manufactured for various industrial applications. These pumps are also produced based on the API 610 standard, which is the international standard for industrial centrifugal pumps.

Features and specifications of OH3 pumps

Structure and design

Single-stage vertical: OH3 pumps are vertical and single-stage, that is, they have an impeller to move the fluid vertically.

Separate shaft: The motor shaft is separate one and connected to the pump using a coupling, which facilitates maintenance and repair.

Installation type: the axis of these pumps is vertical and the inlet and outlet are placed in one line. Due to general installation, they occupy less space than horizontal pumps. These pumps are installed from the bottom on the chassis.

construction materials

Different materials: depending on the type of fluid and working conditions, OH3 pumps can be made of different materials such as stainless steel, cast iron, corrosion resistant alloys and other materials.

Performance and capabilities

High efficiency: optimal hydraulic design that increases efficiency and reduces energy consumption.

Pressure and flow rate: the pump’s ability to transfer fluids with low and medium pressure and variable flow rates depending on industrial needs.

Operating temperature: the ability to work in high temperatures and harsh environments.

Maintenance

Easy access: the possibility of easy disassembly of parts for repairs and maintenance.

Spare parts: the ability to access standard spare parts that reduces pump downtime.

Applications

- Oil and gas: movement of crude oil, oil products and chemicals.

- Petrochemical: transfer of various chemicals in production processes.

- Refineries: processing and transfer of oil products in different units.

- Chemical industry: use in various processes of chemical production.

- Power plants: Boiler feed water pumping and other related applications.

Advantages

- Saving space: due to vertical design and use of less space.

- Durability and stability: due to the use of high quality materials and standard design.

- Reducing operating costs: due to high efficiency and reducing the need for frequent repairs.

- Flexibility: the ability to adapt to different operating conditions and diverse industrial needs.

OH3 pumps are a good choice for many industrial applications due to their vertical design and optimal performance, and with the mentioned features, they can meet the needs of various industries.