What is a Coupling?

Couplings are one of the important components in mechanical and power transmission systems that are responsible for connecting two rotating shafts to each other.

This connection can be fixed or detachable and plays an essential role in the transmission of power and movement between two shafts.

In this article, various types of couplings, applications, and advantages and disadvantages of each will be discussed.

Types of couplings

Couplings are generally divided into two main categories: rigid couplings and flexible couplings.

-

Rigid couplings

Rigid couplings are one of Types of Couplings that designed for precise and firm connection of two shafts and do not have any flexibility. These types of couplings are mostly used in applications that require precise alignment.

Flanged couplings: These couplings include two flanges that are connected to each other with bolts and nuts. These types of couplings are suitable for transmitting large forces and accurate alignment.

Shell couplings: This type of coupling consists of a shell that covers two shafts and is connected to them with bolts and nuts. This type is also suitable for applications that require precise alignment.

-

Flexible couplings

Flexible couplings are another of Types of Couplings that capable of absorbing shocks, oscillations, and minor deviations in shaft alignment. These features make them suitable for applications where perfect alignment accuracy is not possible.

Jaw Couplings: These couplings consist of two jaw halves and an elastomeric element (spider) that is placed between them. This type of coupling can absorb angular and axial deviations.

Disc Couplings: This type of coupling consists of flexible metal discs that can absorb angular and axial deviations and is suitable for high speed applications.

Grid Couplings: These couplings consist of a flexible metal grid that is placed between two shafts and can absorb shocks and fluctuations.

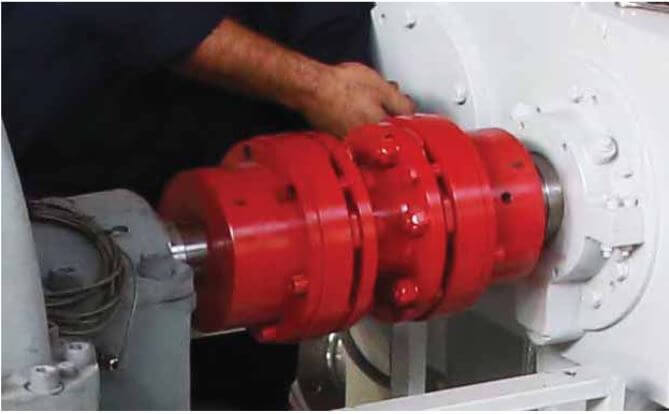

Gear Couplings: This type of coupling consists of two gears with internal and external teeth that can absorb angular and axial deviations and is suitable for transmitting large forces.

Applications of couplings

Couplings have wide applications in various industries. Some of the most important applications of couplings are:

Power generation industries: Power transmission between turbines and generators, and between motors and pumps.

Oil and gas industries: Connecting pumps, compressors, and drilling equipment to drive motors.

Mining industry: connecting material handling equipment, crushers, and heavy machinery.

Automotive industry: connecting different parts of power transmission systems, such as gearboxes and differentials.

Food and pharmaceutical industries: connecting food and pharmaceutical processing equipment to drive motors.

Water and sewage industries: connecting water pumps and purification equipment to drive motors.

Advantages and disadvantages of all types of couplings

Each type of coupling has its own advantages and disadvantages, which must be considered in choosing the most suitable type for the desired application.

Rigid couplings

Advantages:

High alignment accuracy

Full power transmission without any slippage

Simple and durable structure

Disadvantages:

The need for precise alignment of the shafts

Lack of flexibility in absorbing shocks and fluctuations

Need more maintenance due to high wear.

Flexible couplings

Advantages:

The ability to absorb shocks and fluctuations

The ability to compensate for angular and axial deviations

Reduction of vibrations and mechanical noise

Disadvantages:

Power transmission may be accompanied by a slight slip.

More complexity in design and construction

The need for periodic maintenance to replace elastomeric or metal parts

Conclusion

Couplings are critical components in mechanical and power transmission systems, and their correct selection can help improve the efficiency and useful life of the system.

Factors such as power type, speed, shaft alignment, and the need to absorb shocks and fluctuations should be considered in choosing the type of coupling.

Due to the variety of couplings, it is possible to find a suitable option for each specific application.