What is a mechanical seal?

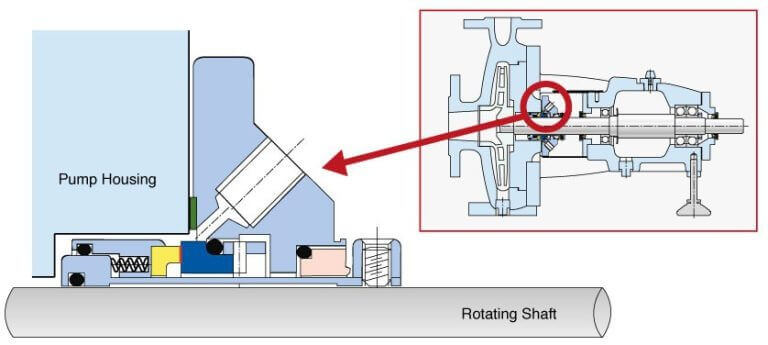

What is a mechanical seal?Mechanical seal is a method to prevent leakage from a chamber through which a rotating shaft passes. This method is familiar in almost all the industrial community and wherever there is a rotating shaft, some type of sealing is needed.

Seal mechanical performance:

Mechanical sealing is used in systems that need to limit the fluid inside a chamber, and usually this chamber is related to pumps and mixers. For example, in sealing a centrifugal pump, the challenge is to get the rotating shaft into the pump, without a large volume of high-pressure water escaping from the chamber. To solve this challenge, a sealing system between the shaft and the body is needed to resist the fluid pressure and bear the friction caused by the rotation of the shaft.

Before the general mechanism of mechanical seal is explained, it is better to review other sealing methods. One of the most used methods is gland packing. In this method, a woven rope-like material is used to fill the void between the shaft and the body.

Packing gland, despite being an old method, is still used in many applications; but the use of mechanical seal is increasing for the following reasons:

- The friction of the rotating shaft wears the gland over time and increases leakage.

- The heat generated due to the friction of the shaft is very high and the shaft will need a lot of cooling.

- To reduce leakage, the glands must apply pressure to the shaft. This pressure increases the input power of the electric motor and reduces the efficiency of the system.

In fact, the mechanical design of the seal has been done to overcome the above problems. The mechanical seal consists of two basic parts; one of the components is fixed and the other rotates until the target set is sealed.

Several simple mechanisms and different parts are used to operate the mechanical seal and connect it to the shaft and fixed part. Mechanical seals are usually of fixed surface or rotating surface type, but in some designs, environmental seals and double edge type are also used. In all cases, it is common to use the following components for sealing.

- The main rotating sealing element: This element is connected to the shaft and is rotated by it, and it is in front of the main fixed sealing element.

- The main fixed sealing element: This element is connected to the fixed body of the pump, mixer or any other device and exerts force on the main rotating element.

- Gathering force: This force is applied to the main sealing elements so that the elements remain connected and sealing is done.

- Fixed and moving secondary seals: seals between mechanical sealing components and shaft and body equipment

A simple seal has three components. The fixed part of the seal is placed on the fixed body and an o-ring or washer can be placed between the fixed and the moving part.

One part of the system, which can be movable or fixed, is always flexibly mounted, and a spring is incorporated to compensate for any deformation of the shaft and its movement due to bearing tolerances and shaft misalignment. While two parts of the mechanical seal are fixed. The part between the fixed parts of the body and the moving part of the shaft needs more attention. This part is the main part of the whole design and its correct operation is essential for the system’s efficiency.

In common mechanical seal designs, the main sealing elements are in contact with each other. Ceramic, carbide, carbon or composite are used in these elements. The sealed fluid moves between the suface of the main elements and forms a stable layer between the two elements.

When the shaft rotates, the sealing elements will heat up and quickly wear and break down without a cooling fluid. The sealing fluid creates a thin layer of lubrication. In the mechanical edge type seal, a thin layer of sealing fluid cools the sealing surface.

Leakage is inevitable for cooling and lubricating the rings that rotate on each other, but the amount must be controlled. To minimize the amount of leakage, the distance between the rings should be as small as possible. For this purpose, the collecting force is used and its amount is determined according to the working range and existing conditions.

The initial cellecting force ensures that the seal will function properly from start. This force is provided by a spring in fixed and variable surface seal designs, which can be a single spring, multiple, a bent metal or elastomer, a flat spring, or a bent spring. Also, the primary force can be created by a magnet. In the mechanical edge seal, bent polymer is used to create the collecting force, and if the material has low resistance, the helical spring is replaced.

The sealing elements must be fixed on the rotating shaft and the fixed body. O-rings, gaskets and other sealing elastomers prevent leakage at the point of contact of elements. The secondary fixed mechanical seal also prevents leakage between components that do not move relative to each other. An example of this is a bushing and a shaft that both rotates but do not move relative to each other.

The secondary movable mechanism prevents the leakage of the parts that move relative to each other. An example of this is a spring-mounted sealing plate, where the plate can move as far as the spring will allow, and the secondary seal prevents leakage between the plate and the part to which the plate is flexibly mounted.

Mechanical sealing of the edge type only requires a fixed secondary seal; Because the deformation of the edge sealing compensates for any displacement of the working parts. All fixed surface and variable surface seals require at least one variable secondary mechanical seal. The reason for this is the rigidity of the elements in contact, which causes the system to leak with any displacement, off-axis of the shaft, volume change due to expansion and axial movement of the shaft. A secondary moving mechanical seal compensates for relative movement between at least one of the sealing surfaces and the component it is mounted on.

The mechanical seal design, materials, fluid conditions and environment are the factors that determine the life of the mechanical seal. Mechanical seals are used for a wide variety of fluids. Each fluid has different lubrication characteristics, but for proper sealing performance, the presence of a thin layer of fluid between the sealing elements is essential.

A layer that has a high thickness increases leakage and allows solid particles to pass through the seal, which will increase wear and corrosion. On the other hand, a layer that is thin will generate heat and decompose the elements. One of the goals of designing a mechanical seal is to keep the contact area of the elements clean and cool so that the sealing function is correct and its lifespan increases.

By using the mechanical design of the seal, it is possible to change the collecting force between the sealing elements and, as a result, adjust the thickness of the fluid layer between them so that the temperature of the contact point of the elements does not rise and the lubrication is done completely. Another method to regulate the thickness of the fluid layer is to change the design and type of elements in contact to improve the vertical force between them.

The selection of the material of the main elements of the mechanical seal has a great effect on the life of the system. Chemical compatibility is only one of the selection criteria. Harder materials have high resistance against corrosive fluids, but if both elements are selected from hard materials, the wear between them will increase and they will not be suitable for fluids without corrosive properties.

Using a softer element or one with suitable materials for lubrication, such as graphite, will reduce friction and losses. Also, the use of hard composite materials reduces friction by providing microscopic holes in the contact surface of the elements.

Another feature that is considered while choosing the material of the elements is the thermal conductivity, which causes the transfer of heat away from the contact surface. The hardness of the surface of the elements and the internal texture of the materials also play a fundamental role in the lifetime of the seal. Keep in mind that many sealing failures are caused by secondary sealing failure due to improper chemical, pressure, and temperature conditions. Metal parts must also be compatible with the type of fluid to avoid corrosion.

Mechanical seal production

The production method of a mechanical seal is based on three sealing points. The first part is the fixed part of the seal that is installed in the pump housing. This part may be sealed with a gasket ring between the fixed part and the pump housing. The second part is the rotating part of the seal, which is usually closed with another ring on the shaft. This sealing point can also be considered fixed. Because this part of the seal rotates with the shaft.

The third part is also installed in a flexible way, both in the static part and in the dynamic part. This part is spring loaded to accommodate any small shaft deflection, shaft movement due to bearing tolerances, and misalignment due to manufacturing tolerances. It should be noted that mechanical seals are the interface between the fixed and moving parts of the seal.

How to choose a mechanical seal

To buy a mechanical seal and choose a mechanical seal, you must identify the influencing factors and make a correct choice. These factors include:

– Pump speed (RPM)

– The working temperature of the pump or the temperature that must be tolerated by the mechanical seal.

– The diameter of the shaft and the assembly size of the length of the mechanical seal

– Pumping working pressure and its maximum pumping pressure.

– Selection of mechanical seal material according to the type of fluid, which include

Up to 80 degrees Celsius = NBR material

80 to 180 degrees Celsius = Wyton material

Above 180 degrees Celsius = a type of Teflon and special elastomer

Choosing the type of mechanical seal surface, according to the pump speed, pressure and type of fluid

Fluids with small particles = silicon carbide

Fluids without small particles = carbon (if the RPM is normal)

Fluid with high sensitivity coefficient and without leakage = tungsten carbide

Pumps with heating problems for mechanical seal = ceramic

If the mechanical seal works dry, it will quickly crack and wear out, so it should not work dry.

Types of mechanical seals:

Mechanical seals differ in design, the way parts are placed, and the mechanism of repelling the force applied to the surfaces. There are several common types of mechanical sealing, which include:

Balanced mechanical seal:

This type is called a system where the forces entering the sealing surfaces are neutralized. Due to the low force in the sealing elements, lubrication is done homogeneously on the surfaces, and as a result, the lifespan of this type of sealing is long. Balanced mechanical seal is suitable for high pressure applications (above 14 atmospheres) and is also a good choice for fluids with low lubrication properties.

Unbalanced mechanical seal:

This type of mechanical seal is considered an economic choice and has less leakage due to more force on the surfaces. In contrast, the lifetime of an unbalanced mechanical seal is low. This option is suitable for low pressures and is not recommended for hydrocarbons.

Spring mechanical seal:

In this type, one or more springs are used to create the collecting force. Springs can be placed in fixed or moving elements. Spring-loaded seals can also be used for high pressures, but due to the presence of elastomers below the main sealing surface, there is high wear.

Mechanical seal without spring:

In this type, a metal or elastomer is used to create the collecting force. The springless mechanical seal is suitable for applications with high temperature and contaminated fluid, and its suitable operating range is low to medium pressure. Both spring and unspring designs can be balanced or unbalanced.

Mechanical seal cartridge:

In this type, all the parts are assembled in a single set, and as a result, the possibility of error in the assembly is reduced and the duration of the seal replacement is increased.

Selection criteria:

Using the compiled standards to choose a seal is the best approach to choose the type and material of parts. One of the reputable and well-known organizations active in this field is the American Petroleum Institute (API), which has developed the widely used API 682 standard for mechanical seal selection. This standard is informational only as an appendix that contains guidance only and does not include design requirements. Many petrochemical and industrial applications are covered in this standard, but some more specific applications cannot be found.

In seals that are used for pumps with relatively safe fluid, single type can be used; Because leakage to atmospheric pressure is not dangerous and is easily controlled. The use of double sealing can better control the leakage by enclosing the fluid, but even in this type, a small amount of leakage may remain.

If the conditions are such that leakage is not allowed, a triple seal that uses a high-pressure fluid mechanism as a barrier is used. In the fourth edition of the API 682 standard, in addition to determining the amount of leakage, the type of fluid, the degree of corrosiveness and other risks are also considered, and different types of sealing parts are shown with different codes based on their resistance to different fluids.

Before the final selection, in addition to the mentioned criteria, other considerations such as fluid characteristics pump operation without fluid, leak detection strategies, leak discharge method, and fluid contamination should also be considered.

Mechanical seal maintenance:

The mechanical seal is a part of the pumping system whose performance is critical and its maintenance is usually forgotten. Excessive leakage from the seal due to improper maintenance or working conditions beyond the permissible limits can cause various hazards such as ignition, health or environmental problems; therefore, it is necessary to use a regular and practical sealing maintenance program to ensure correct operation and increase the lifespan. The following are the things that should be considered in maintaining this system.

Estimation of working conditions:

Temperature, pressure and speed are among the factors that affect the wear of sealing elements and the increase of leakage; therefore, it is necessary to know the operating conditions to choose a suitable sealing system. The combination of process variables for mechanical sealing creates special conditions that require system adjustments to accommodate problems such as evaporation, freezing, or overheating.

It is very difficult to keep the efficiency of the sealing system high for applications where there is high temperature, pressure and speed or where the viscosity of the fluid is high. In such a situation, it is recommended to use strong and resistant seals to increase the service and repair time of the system.

Durability of sealing surfaces against fluid:

In most systems, the fluid being pumped is also used as the lubrication fluid. Fluid properties, like sealing properties, are a function of temperature and working pressure that must be considered. These properties include the thickness of the layer between the elements, purity, toxicity and flammability. Hard-hard seals are more suitable for dirty fluids containing solid particles, but without a fluid layer between them, they will wear out sooner. In contrast, hard-soft seals will last longer in the absence of lubricating fluid.

Attention to the reasons for the wear of sealing surfaces:

Excessive leakage is usually a sign of wear on the contacting surfaces, but this problem can be caused by more serious problems such as bearing failure and shaft bending. If the wear is due to the contact of rough surfaces, we can see its signs, which are the presence of grooves and chips on the surface.

Reduce vibrations:

Try to use the pump close to the best performance point. When you move a lot away from this point, cavitation will be created in the pump and as a result, the amount of pump vibrations will increase. The sealing system and especially parts such as o-rings, polymers, springs, driving pins and adjustment screws are sensitive to vibration, and the presence of high vibrations will reduce their lifespan.

Proper lubrication:

Mechanical seals depend on an oil film between contacting surfaces to control heat and friction. In most cases, the pumped fluid provides the required oil layer while contacting the sealing surfaces; therefore, to protect the seal, the pump should be prevented from running without fluid.

To be sure, controllers equipped with a flow sensor or a pump performance monitor can be used to avoid problems. In general, the performance of the sealing system in applications where the pump works continuously is better than in applications where the pump is cycled on and off. On average, the time of using mechanical sealing is considered to be at least two years. As mentioned earlier, this duration depends on variables, working conditions and design constraints. Familiarity with the system and its limitations can help to prevent, recognize and solve sealing problems.

Mechanical seal replacement and installation:

The general process and method of assembling and disassembling the parts of each manufacturer is different, but the general principles of mechanical seal operation are the same. In the following, the general points that should be considered in the installation and replacement of the seal are stated.

Initial shaft inspection: Make sure the shaft is clean and free of dirt, chips, and metal. Also check the area where the o-rings are located more carefully. Measure the shaft diameter to make sure it is within the tolerance allowed for the seal.

Inspect new sealing elements and parts to ensure that no damage has occurred during manufacturing or shipping. The distance between the outer diameter and the inner diameter of the plates of the connecting rings must be constant and stable. This distance may be out of the original state during the transfer. To reset, press the rings with your fingers until they return to their original position. If this issue is ignored, the amount of leakage in the sealing will be more than the permissible limit.

Adjusting the proper sealing height: To adjust this height, there are small plastic parts that must be placed on the side of the connecting rings. To install, press these parts slightly against the wall of the sealing tank. If the amount of pressure is high, the spacers will be bent and the height of the rings will be out of the proper range. After adjustment, tighten the screws and remove the spacers.

O-rings of elastometers must be installed with utmost precision and minimum pressure. Also, the amount of oil needed to install them is very small. The oil is only used to facilitate the installation of the parts and does nothing to seal the system. If too much oil is used in the mechanical seal installation, the excess oil will move to the parts where the sealing elements are in contact and have high temperature, causing burns, seal damage and leakage.

Installing the main ring: The main ring made of carbon or silicon carbide is divided into two parts, and a protective ring is used to hold these two parts. Place the main ring on the surface of the rotor and set it in the center.

One of the most important points of using and repairing a mechanical seal is the degree of tightening the seal. Due to the importance of this issue, this issue will be explained in detail below. When one of the valves in the house is leaking, tightening the valve usually fixes the problem, but if there is a large mechanical leak, over-tightening will make the problem worse. For correct adjustment, observe the following points:

Read the manufacturer’s instructions and follow them carefully

Never press the parts together. Sealing parts are easily damaged and expensive to replace.

The technician’s work space and hands must be clean. Even a small amount of contamination can damage the seal.

Do not torque the fasteners more than the required amount.

Over-tightening the gasket places unnecessary stress on the contacting surfaces. This pressure will cause the failure of the seal due to mechanical shock. Mechanical shock has reasons such as improper bearings, cavitation, high torque, unbalanced load and shaft deviation, and it is very common due to improper sealing adjustment.

Also, too much tightening will cause pressure on the springs and intensify the force between the sealing surfaces. This issue causes the sealing temperature to be higher than usual and the wear of the surfaces to occur faster. Also, one of the results of excessive tightening is the creation of distortion in the fixed elements of the mechanical seal, which causes damage to the gaskets and their deformation, which all these factors cause more leakage; So if you come across a case with a leaky mechanical seal, in most cases, loosening the seal will give better results than tightening it.

Repair and fault finding:

Seal mechanic is often faced with dangerous, toxic and flammable fluids and must work under harsh conditions such as high speed, temperature and pressure; therefore, sealing wear is inevitable, especially in working conditions close to the highest limit for the system. The choice of whether to repair or replace the seal is up to the technician and the user, and choosing repair over replacement to reduce costs is completely understandable.

The repair process is a little different for different systems, but in general, after disassembling the parts, some of them are cleaned and others, such as elastomers and metal parts, are replaced. The final result should be such that the performance is as good as a new system.

Heat damage:

The creation of radial cracks from the center of metal and ceramic rings is due to high heat. According to the Fluid Sealing Association (FSA), these cracks act like cutting edges on sealing surfaces, which will eventually cause sealing wear due to their abrasive properties. This problem occurs when a fluid with low density and high speed and pressure is used. The result of this process is fluid dripping regardless of whether the shaft is moving or stationary.

Factors affecting this problem are insufficient amount of fluid for lubrication, cooling less than the required amount and evaporation of fluid on the sealing surface. As a precaution, make sure there is enough fluid on the sealing surfaces. Other measures to solve this problem include:

– Checking the pressure inside the chamber to ensure that the fluid does not evaporate

– Checking the sealing settings to ensure the correct height of the elements

– Checking the tolerances between the shaft and the main ring at working temperature

– Checking the presence of distortion in the connecting rings

High wear and groove:

Groove wear usually occurs in connecting rings. The main rim has a 360 degree groove in the connecting rim. The sign to recognize this case is fluid dripping from the seal independent of the movement or stability of the shaft. There are many factors that cause grooves. Poor lubrication, especially when the surfaces are hard, is one such factor. In rings that are made of soft materials, fluid corrosion will cause grooves.

To prevent leakage due to groove growth, do the following:

– Increasing the amount of cooling in the sealing surfaces

– Checking the presence of corrosive particles in the fluid

– Checking the presence of blockage in the sealing chamber

Coking:

The coking process creates a black layer on the part that is under atmospheric pressure. This created layer causes severe wear of the sealing surfaces, which is usually done by oxidation. Coking symptoms occur when the mechanical seal operates under high temperatures or in the presence of dirty fluid with solid particles.

Flushing the sealant from an external source or replacing the sealant surfaces with a hard type that resists oxidation can delay coking. Steam is used to clean the resulting layer.

Cavity and corrosion:

Chemical effects are one of the factors of corrosion and creating holes in mechanical seals. This usually happens when the wrong material is used for the sealing parts. Corrosion also occurs as a result of the pump working without fluid. To avoid this damage, check the chemical compatibility of the fluid with the sealing surfaces and always consider normal working conditions without cleaning processes when selecting parts.

Burns of sealing surfaces:

This is a sign of heat damage and is recognized by the circular areas raised from the carbon surface of the seal. Burns are one of the common causes of sealing leaks; because the burnt part increases the distance between the sealing elements. The sealing surfaces must be very smooth and the presence of the smallest amount of pollution, such as burns, will cause leakage.

Burns are more common in pumps that are used frequently. Also, in the presence of fluid with high viscosity, the possibility of burns increases. When the temperature of the sealing surfaces increases, the high-viscosity fluid in the cavities of the surfaces is quickly pushed out.

Improper cooling and fluid circulation on sealing surfaces also increase the possibility of burns. To reduce the risk of burns, minimize frequent switching on and off. If possible, use impervious surfaces for mechanical flooding to eliminate the possibility of corrosive fluid penetration.

3 thoughts on “What is a mechanical seal?”